Mastering The Craft: The Ultimate Guide To Duct Machines

Are you looking to enhance your knowledge and skills in the world of duct machines? Look no further, as we have the ultimate guide to help you master the craft. Whether you're new to duct machines or looking to level up your expertise, this comprehensive guide will provide you with all the information you need to become a duct machine pro. From understanding the different types of duct machines to mastering their operation and maintenance, this guide has got you covered. Dive in and take your duct machine skills to the next level!

Understanding the Basics of Duct Machines

Duct machines are essential tools in the HVAC and sheet metal industry, used for fabricating ductwork for heating, ventilation, and air conditioning systems. In this ultimate guide, we will delve into the basics of duct machines, providing a comprehensive understanding of their functionality, types, and applications.

Duct machines are specialized equipment designed for the fabrication of ductwork, which is an integral component of HVAC systems. These machines are used to process sheet metal into ducts of various shapes and sizes, including rectangular, round, and oval ducts. They are capable of performing a range of operations such as cutting, bending, folding, and seaming, enabling the production of precise and high-quality ductwork.

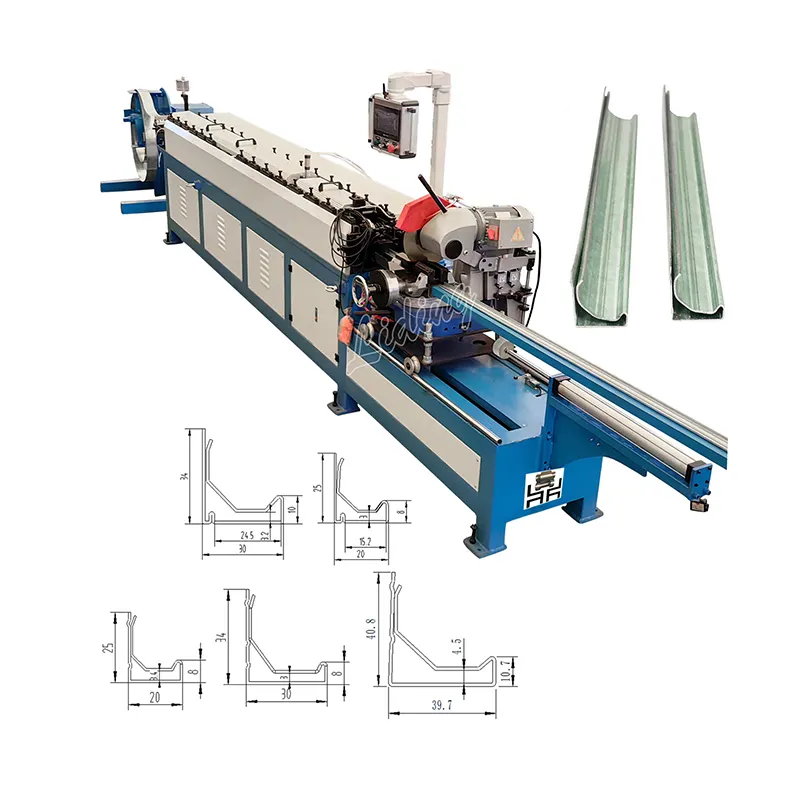

Types of Duct Machines

There are several types of duct machines available in the market, each designed for specific fabrication processes. The most common types include:

1. Duct Cutting Machines: These machines are used to cut sheet metal into the desired dimensions for ductwork. They utilize cutting tools such as shears or lasers to achieve precise and clean cuts.

2. Duct Bending Machines: As the name suggests, these machines are employed to bend sheet metal into the required shapes for ducts. They utilize press brakes or roll formers to achieve accurate bends along straight or curved sections of the ductwork.

3. Duct Folding Machines: These machines are utilized to create folds or seams in the sheet metal, which are essential for joining different sections of the ductwork. They can perform various folding operations, such as Pittsburgh locks, TDF (Transverse Duct Flange), and S-lock seams.

4. Duct Seaming Machines: These machines are used to seam the edges of the sheet metal together, ensuring airtight and leak-free duct joints. They can employ methods such as lock forming, clinching, and flanging to create strong and durable seams.

Applications of Duct Machines

Duct machines find widespread applications in the HVAC and sheet metal industry, where they play a crucial role in the fabrication of ductwork for residential, commercial, and industrial buildings. They are utilized by HVAC contractors, sheet metal fabricators, and ductwork manufacturers to produce ducts for air distribution, ventilation, and exhaust systems.

Furthermore, duct machines are essential for custom fabrication projects, where unique duct designs and shapes are required to cater to specific building layouts and HVAC system requirements. Whether it’s a simple rectangular duct or a complex spiral duct, these machines are capable of meeting the diverse fabrication needs of the industry.

In conclusion, understanding the basics of duct machines is pivotal for anyone involved in the HVAC and sheet metal industry. With the right knowledge of their functionality, types, and applications, professionals can master the craft of ductwork fabrication and excel in delivering high-quality HVAC systems. As technology advances, duct machines continue to evolve, offering more efficient and precise fabrication solutions for the industry. It is crucial for professionals to stay informed about the latest advancements in duct machine technology to stay ahead in the competitive market.

Choosing the Right Duct Machine for Your Needs

Duct machines are essential tools for the HVAC industry, as they are used to fabricate and shape ductwork for heating, ventilation, and air conditioning systems. Choosing the right duct machine for your needs is crucial to ensure efficiency, accuracy, and productivity in your duct fabrication processes. With the wide range of duct machines available on the market, it can be overwhelming to select the best one for your specific requirements. This ultimate guide will provide you with the knowledge and insights to help you master the craft of choosing the right duct machine for your needs.

First and foremost, it is important to understand the different types of duct machines available. There are various types of duct machines, including plasma cutting machines, spiral duct machines, pittsburgh lock machines, and flanging machines. Each type of duct machine is designed for specific ductwork fabrication processes, such as cutting, forming, and joining. Understanding the specific functions and capabilities of each type of duct machine is essential in determining which one will best suit your needs.

When choosing a duct machine, it is crucial to consider the size and capacity of your ductwork fabrication operations. If you have a high volume of ductwork fabrication, you will need a duct machine with a larger capacity and faster production capabilities. On the other hand, if your operations are smaller in scale, a smaller and more compact duct machine may be more suitable. It is important to assess your current and future needs to ensure that the duct machine you choose can meet the demands of your fabrication operations.

The quality and reliability of the duct machine are also important factors to consider. Investing in a high-quality and reliable duct machine will ensure long-term efficiency and productivity in your duct fabrication processes. Look for reputable manufacturers and suppliers that offer durable and well-built duct machines with a proven track record of performance and reliability. Additionally, consider the availability of spare parts and technical support, as this will be essential for the maintenance and upkeep of your duct machine.

Another important aspect to consider is the specific features and capabilities of the duct machine. For example, if you require precision cutting for intricate ductwork designs, you will need a duct machine with advanced cutting technologies and capabilities. If you work with a wide range of duct sizes and materials, a duct machine with versatile capabilities and adjustable settings will be essential. Consider the specific features that are crucial for your ductwork fabrication processes and ensure that the duct machine you choose can meet these requirements.

In conclusion, mastering the craft of choosing the right duct machine for your needs requires a comprehensive understanding of the different types of duct machines, as well as careful consideration of your specific requirements, size, capacity, quality, reliability, and features. By taking the time to research and evaluate your options, you can make an informed decision and invest in a duct machine that will significantly enhance the efficiency, accuracy, and productivity of your ductwork fabrication operations. Choose wisely, and master the craft of duct machine selection for optimal results in your HVAC business.

Operating and Maintaining Your Duct Machine

Duct machines are essential tools used in the HVAC (Heating, Ventilation, and Air Conditioning) industry for creating ductwork for ventilation systems. Whether you are a seasoned professional or just starting out in the field, understanding how to operate and maintain a duct machine is crucial for producing high-quality ductwork efficiently and safely.

Operating a Duct Machine

Before operating a duct machine, it is important to familiarize yourself with its components and functions. Most duct machines consist of a mainframe, a coil holder, a straightener, and various forming stations. The mainframe is the central part of the machine and houses the motor, controls, and other essential parts. The coil holder is used to hold the metal sheet or coil that will be formed into ductwork, while the straightener ensures that the metal sheet is properly aligned before it enters the forming stations.

To operate the duct machine, start by loading the metal sheet or coil into the coil holder and feeding it through the straightener. Next, set the machine to the desired specifications for the ductwork, such as the dimensions, shape, and any other necessary features. Once everything is set up, start the machine and carefully monitor the forming process to ensure that the ductwork is being produced accurately and without any issues.

Maintaining a Duct Machine

Proper maintenance of a duct machine is essential for keeping it in good working condition and preventing breakdowns or malfunctions. Regular maintenance tasks include cleaning, lubricating, and inspecting the various components of the machine. Cleaning the machine involves removing any dust, debris, or metal shavings that accumulate during operation, as these can affect the machine's performance and accuracy. Lubricating the moving parts of the machine helps reduce friction and wear, prolonging the lifespan of the machine and ensuring smooth operation. Inspecting the machine for any signs of damage, wear, or misalignment is also important, as addressing these issues promptly can prevent more serious problems from arising.

In addition to routine maintenance, it is crucial to follow the manufacturer's recommended maintenance schedule and procedures for the specific duct machine you are using. This may include replacing worn or damaged parts, calibrating the machine, and performing any necessary adjustments or repairs.

Safety Considerations

When operating and maintaining a duct machine, it is essential to prioritize safety at all times. This includes wearing appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection, to prevent injury from flying debris, sharp edges, and loud noises. Additionally, always follow the machine's safety guidelines and procedures, such as locking out the machine before performing maintenance, to prevent accidental startup or other dangerous situations. Lastly, be aware of any potential hazards associated with the specific type of duct machine you are using and take appropriate precautions to avoid accidents.

Mastering the craft of operating and maintaining a duct machine is crucial for achieving high-quality ductwork and ensuring the safety of yourself and others. By understanding the components and functions of the machine, following proper operating and maintenance procedures, and prioritizing safety at all times, you can effectively utilize a duct machine to produce exceptional ductwork for HVAC systems.

Advanced Techniques and Tips for Duct Machine Mastery

When it comes to working with duct machines, mastering advanced techniques and tips can make all the difference in achieving the highest levels of efficiency and precision. In this ultimate guide to duct machines, we will explore the advanced techniques and tips that will help you elevate your craft and become a master in the field.

Before delving into the advanced techniques, it's important to have a solid understanding of what duct machines are and their primary functions. Duct machines are essential equipment used in the HVAC (Heating, Ventilation, and Air Conditioning) industry for fabricating ductwork. They are designed to handle various tasks such as cutting, bending, forming, and assembling sheet metal into ducts used for air distribution in buildings. In essence, duct machines play a crucial role in the manufacturing and installation of ductwork, making them an indispensable tool for HVAC professionals.

Now that we have a clear understanding of the importance of duct machines, let’s dive into the advanced techniques and tips for mastering their use:

1. Precision Cutting: Achieving precise and clean cuts is crucial for ensuring the proper fit and functionality of ductwork. Advanced techniques for precision cutting involve using specialized cutting tools and paying close attention to measurements and angles. Additionally, mastering the use of advanced cutting features on duct machines, such as laser-guided cutting or computer-controlled cutting, can greatly enhance precision and efficiency.

2. Complex Bending: Duct machines are equipped with bending capabilities to create complex shapes and angles in ductwork. Mastering the art of complex bending involves understanding the full range of bending capabilities of the machine, including multi-axis bending and variable radius bending. Advanced techniques for complex bending also involve using custom tooling and incorporating intelligent software to optimize the bending process.

3. Efficiency in Forming: Forming sheet metal into specific shapes and sizes is a fundamental aspect of ductwork fabrication. Advanced techniques for maximizing efficiency in forming include utilizing automated forming sequences, programming custom forming operations, and leveraging the full speed and power of the machine to streamline the forming process.

4. Assembly and Joining: Properly assembling and joining ductwork is essential for ensuring airtight, leak-free systems. Advanced techniques for assembly and joining involve using specialized fastening methods, such as clinching or welding, and employing advanced joining features on duct machines, such as automated seam closing and flange forming.

5. Integration with CAD/CAM Systems: One of the most advanced techniques for duct machine mastery is integrating the machine with Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) systems. This integration enables seamless transfer of design data to the machine, allowing for automated programming, optimization of cutting and forming operations, and precise replication of complex ductwork designs.

In conclusion, mastering the craft of duct machines requires a deep understanding of their capabilities and the implementation of advanced techniques and tips. By honing your skills in precision cutting, complex bending, efficiency in forming, assembly and joining, and integrating with CAD/CAM systems, you can take your duct machine mastery to the next level and become a leader in the HVAC industry.

Troubleshooting Common Issues with Duct Machines

Duct machines are crucial tools in the HVAC industry, as they are used to fabricate ductwork for heating, ventilation, and air conditioning systems. However, like any other machinery, duct machines can experience common issues that may hinder their performance. In this article, we will delve into some of the most common problems that arise with duct machines and provide troubleshooting tips to help you overcome these challenges.

One common issue that duct machine operators encounter is irregular cutting. This can result in jagged edges and inaccurate dimensions, which can compromise the quality of the ductwork. Irregular cutting can be caused by a dull blade or misaligned cutting components. To troubleshoot this issue, start by inspecting the blade for any signs of wear or damage. If the blade is damaged, it will need to be replaced. Additionally, check the alignment of the cutting components and make any necessary adjustments to ensure they are properly positioned.

Another common issue with duct machines is poor bending accuracy. When ductwork is not bent to the correct angles or dimensions, it can lead to air leakage and reduced system efficiency. Poor bending accuracy can be caused by worn-out or improperly adjusted bending dies. To address this issue, examine the bending dies for any signs of wear and tear. If the dies are worn, they should be replaced to ensure precise bending. It is also important to regularly adjust the bending components to maintain their accuracy.

Additionally, duct machine operators may encounter issues with material feeding. Uneven material feeding can lead to inconsistent ductwork and waste of materials. This can be caused by a dirty or faulty feeding mechanism. To troubleshoot this problem, clean the feeding mechanism thoroughly to remove any debris or buildup that may be obstructing the material flow. If the feeding mechanism is still not functioning properly, inspect it for any signs of damage and make any necessary repairs or replacements.

Furthermore, duct machines may experience issues with locking and seaming. Inaccurate locking and seaming can result in weak joints and air leakage in the ductwork. This can be caused by worn-out or misaligned locking and seaming components. To address this issue, inspect the locking and seaming components for wear and tear, and replace them if necessary. It is also important to ensure that the components are properly aligned to achieve tight and secure duct joints.

In conclusion, duct machines are essential tools in the HVAC industry, but they can experience common issues that may affect their performance. By understanding these common problems and implementing the troubleshooting tips provided, duct machine operators can ensure that their machinery operates effectively and produces high-quality ductwork. Regular maintenance and inspections are key to preventing and addressing these issues, ultimately leading to improved efficiency and productivity in duct fabrication.

Conclusion

In conclusion, mastering the craft of duct machines is essential for any company in the industry. With our 9 years of experience, we have learned the ins and outs of this essential equipment and are prepared to guide and support others in their journey to mastery. By investing in top-quality duct machines and understanding the best practices for their use, companies can ensure efficient and effective operations. With the ultimate guide to duct machines at your disposal, there’s no limit to the success you can achieve in this industry.